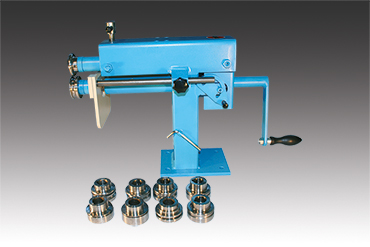

Beading and Flanging Machine

Model M and EL

Construction and Design

Construction and Design

- designed for beading, flanging and wire inserting works

- advance of the top roller by means of threaded spindle

- axially adjustable bottom roller

- guidance of the workpieces through an adjustable stop

Accessory

Accessory

Set of beading dies standard equipment

2 pairs of wiring rollers BA + BC

1 pair of necking rollers F

1 pair of folding rollers ZA

1 pair of beading rollers S = 6 mm

1 pair of crimping rollers E = 30 mm

1 pair of swaging rollers V, 2,5 mm

1 pair of swaging rollers V, 4,0 mm

1 pair of swaging rollers V, 5,0 mm

Special dies

Beading rollers S, SK

Wiring rollers BA, BE, BM, BD

Elbow rollers KA, KB

Seaming rollers ZB

Cutting rollers M

Special dies on request

Optional Accessory

- Electric motor drive,

with geared motor 0,37 KW

speed infinitely variable,

right and left-hand rotation

centre to centre distance between rollers |

Throat depth |

max. sheet thickness |

Working height above table |

Types

|

|---|---|---|---|---|

| 63 | 200 | 1,00 | 250 | M |

| 63 | 200 | 1,00 | 250 |

EL |

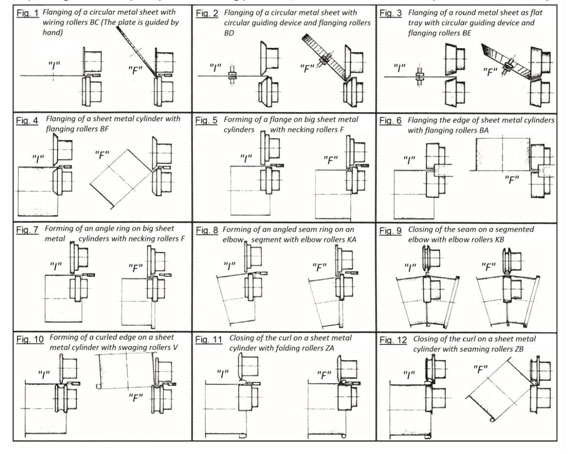

Examples of forming steps on bending machines

I = Initial Position F = Final Position

Depending on the complexity of the forming processes, one or more intermediate positions are necessary!

| We reserve the right to change the illustrations and technical changes explicitly For further informations and technical datasheets, do not hesitate to contact us. |